Ground anchors make a significant contribution to a structure’s stability during the course of its design life.

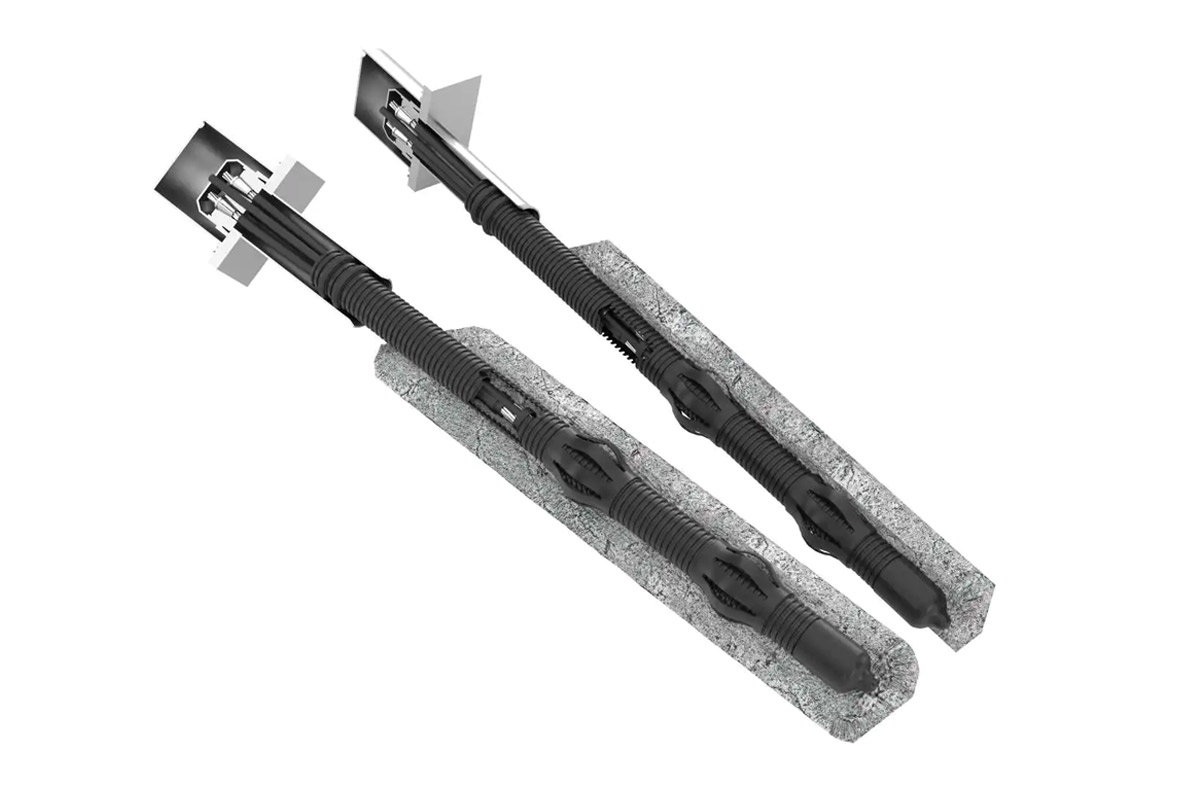

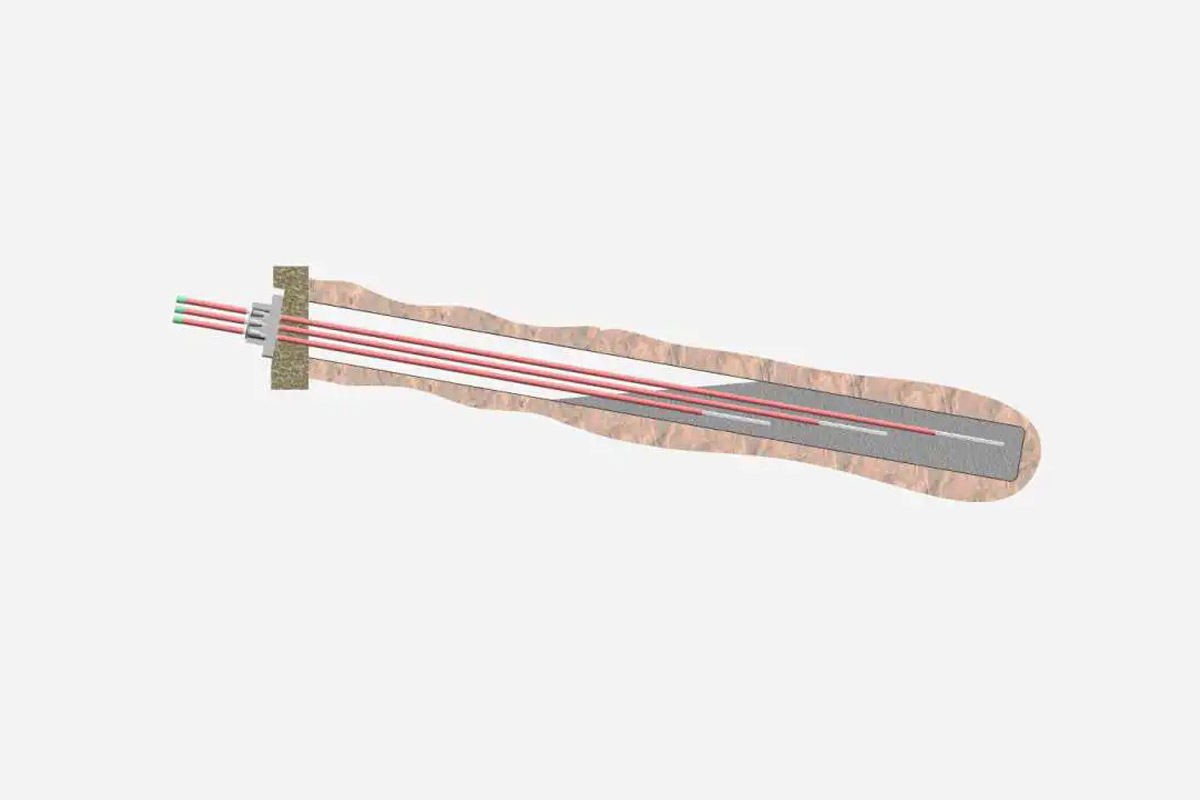

Characteristics

- Ground anchors are distinctive in that they may actively constrain constructions, which makes them

- By supplying a compressive load to a structure, anchors prevent movements.

- A variety of remote monitoring services are offered by data-enabled anchors, promoting reasoned decision-making.

Anchors are used in

- Ground anchors are being used more frequently as they make it possible to build in densely populated places. The decrease in area available for conventional construction techniques is what caused this surge.

- Removable anchors may be utilised where there is little available easement. Engineers can employ composite cuttable anchors for projects when additional underground construction, such as nearby developments or tunnels, is envisaged.