Fast installation and stripping are made possible by forming methods, which may also result in labour cost reductions.

Here at DY.CO, we offer the broadest selection of materials for building industrial, commercial, and residential structures in Europe. DY.CO

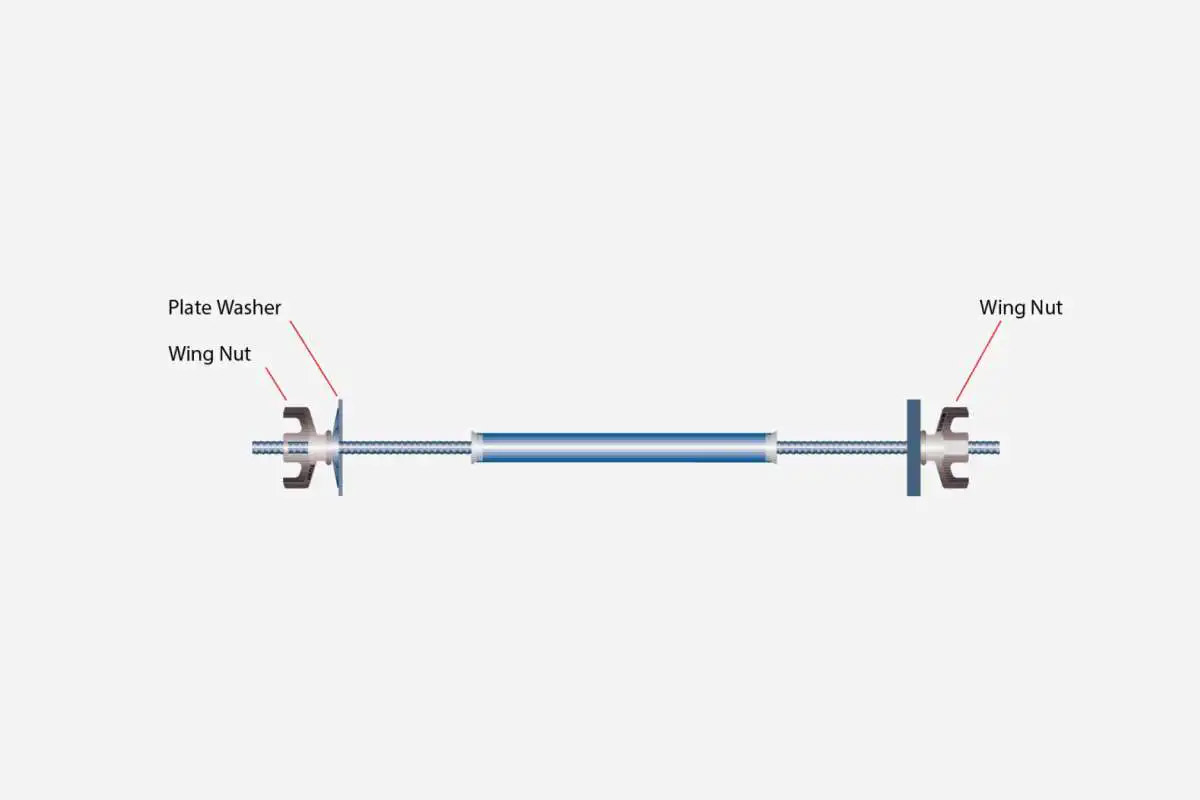

creates, produces, and offers a broad selection of form ties and concrete accessories outside the European zone, such as taper ties, shebolts, and through ties.

Forming systems are used in

All across the world, forming systems are used in infrastructure. concrete products and accessories adhere to and are routinely reviewed both internally and externally in accordance with worldwide industry standards.