World-famous constructions that use bonded post-tensioning systems from include these systems.

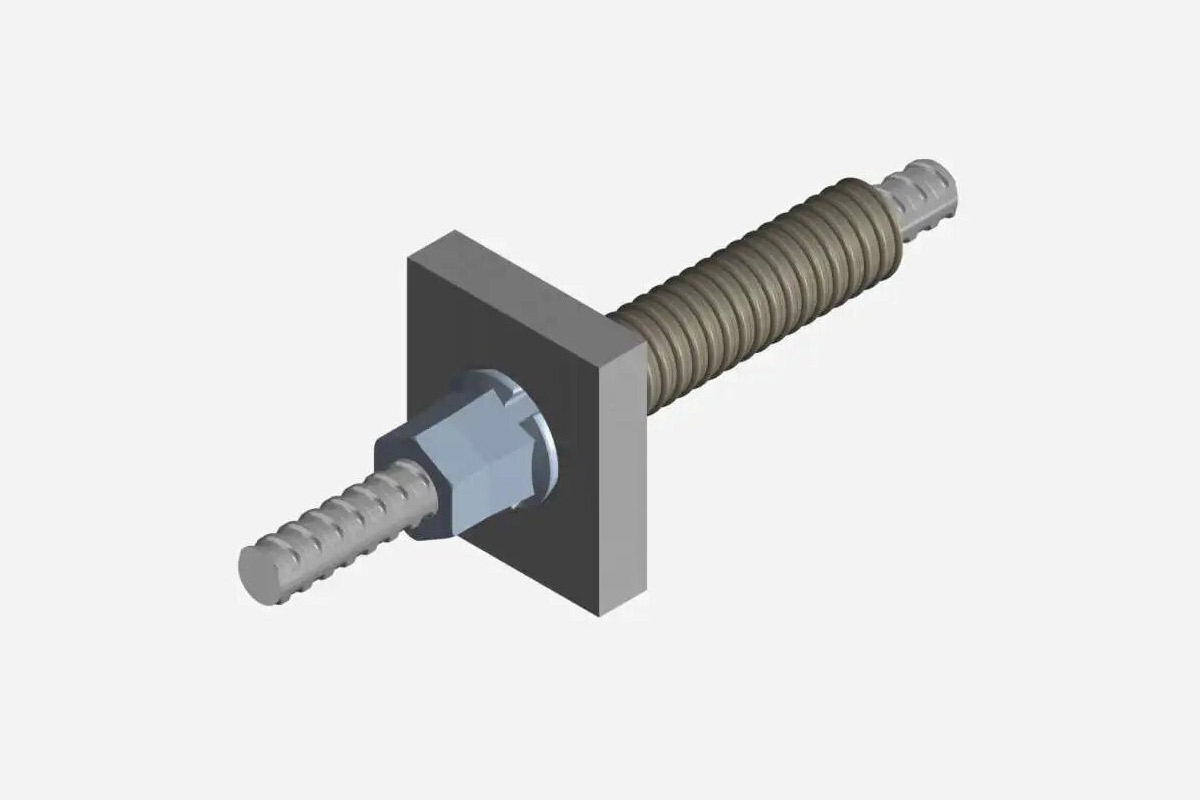

Strands or ThreadbarsTM are used in new construction—as well as to enhance or repair infrastructure—by the dependable and long-lasting bonded post-tensioning systems.

The systems can be applied to concrete floor slabs in multi-story buildings and provide transversal post-tensioning, longitudinal stressing of bridge girders, transversal stressing of bridge decks, and concrete floor slabs.